LIGHT BAR PART 2

#32

ORIGINAL: NJTEX

I see your point. A bolt that long would also cause other problems if one wanted to remove it later after several years outside. What about doing the tube in two parts? One part has the 6mm tread and sleeve with 1/4-20 internal treads at the top and the second part of the tube is welded inside of the light bar. Then use a longer 1/4-20 bolt to hold the light bar to the roof stand-off?

ABS plastic can't withstand cycling loads very well especially with temperature variation too. If you can fix the front of your bar with a secure metal to metal connection, you've got the best solution.

ORIGINAL: hilljob26

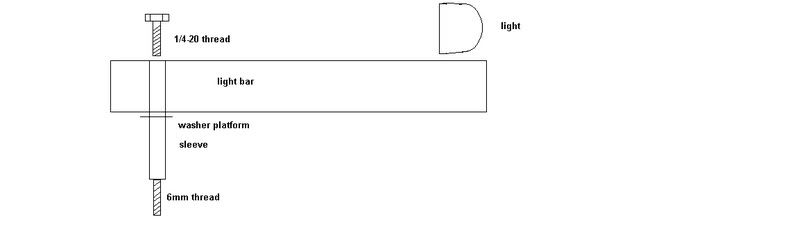

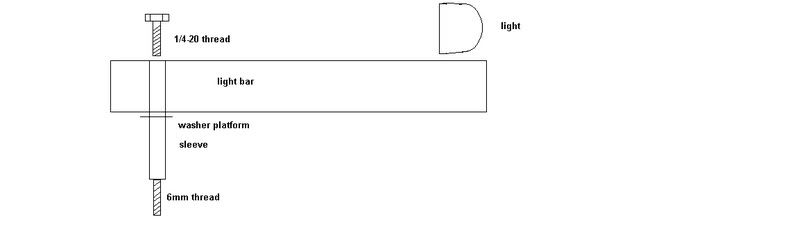

you could do that,but i can find a bolt that long,it take a 6mm thread,and you would have to drill a hole through the bar big enough to fit a socket,it rests pretty good,it does not have very much bounce at all,i think my light bar looks killer,that front mounts does need something defferent,i wonder if i made a tube and welded a threaded end and drilled and tapped the top,kinda like this,i would have to drill a hole in the light bar,weld a washer to the tube.kinda like this

you could do that,but i can find a bolt that long,it take a 6mm thread,and you would have to drill a hole through the bar big enough to fit a socket,it rests pretty good,it does not have very much bounce at all,i think my light bar looks killer,that front mounts does need something defferent,i wonder if i made a tube and welded a threaded end and drilled and tapped the top,kinda like this,i would have to drill a hole in the light bar,weld a washer to the tube.kinda like this

ABS plastic can't withstand cycling loads very well especially with temperature variation too. If you can fix the front of your bar with a secure metal to metal connection, you've got the best solution.

#33

ORIGINAL: KS Trekker

What about using a socket head cap bolt instead of the hex head 1/4 x 20? The hole thru the top if the bar could be significantly smaller since you only need to get a hex key or Torx bit in there.

ORIGINAL: NJTEX

I see your point. A bolt that long would also cause other problems if one wanted to remove it later after several years outside. What about doing the tube in two parts? One part has the 6mm tread and sleeve with 1/4-20 internal treads at the top and the second part of the tube is welded inside of the light bar. Then use a longer 1/4-20 bolt to hold the light bar to the roof stand-off?

ABS plastic can't withstand cycling loads very well especially with temperature variation too. If you can fix the front of your bar with a secure metal to metal connection, you've got the best solution.

ORIGINAL: hilljob26

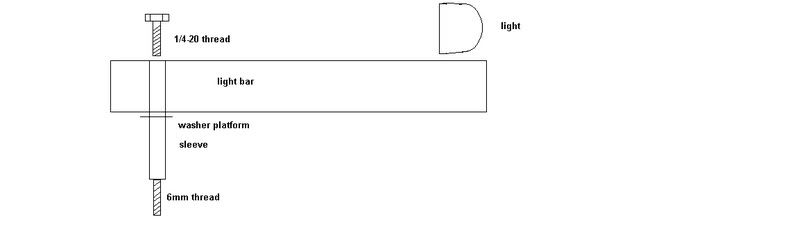

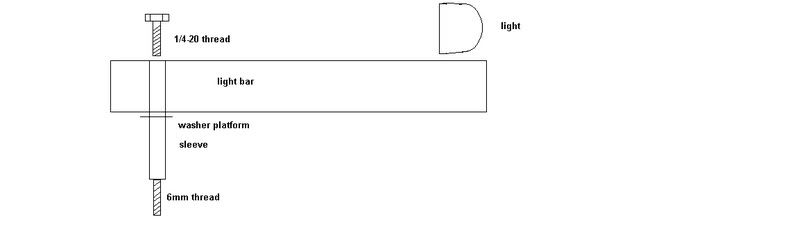

you could do that,but i can find a bolt that long,it take a 6mm thread,and you would have to drill a hole through the bar big enough to fit a socket,it rests pretty good,it does not have very much bounce at all,i think my light bar looks killer,that front mounts does need something defferent,i wonder if i made a tube and welded a threaded end and drilled and tapped the top,kinda like this,i would have to drill a hole in the light bar,weld a washer to the tube.kinda like this

you could do that,but i can find a bolt that long,it take a 6mm thread,and you would have to drill a hole through the bar big enough to fit a socket,it rests pretty good,it does not have very much bounce at all,i think my light bar looks killer,that front mounts does need something defferent,i wonder if i made a tube and welded a threaded end and drilled and tapped the top,kinda like this,i would have to drill a hole in the light bar,weld a washer to the tube.kinda like this

ABS plastic can't withstand cycling loads very well especially with temperature variation too. If you can fix the front of your bar with a secure metal to metal connection, you've got the best solution.

#35

hey hill job. you just let me know when your ready to make that bull bar. lol. i sent you another pm. hopefully ill be ready by then. debating.. spend money on me for christmas,or buy other people gifts... lololol

#36

ORIGINAL: NJTEX

The inside of the light bar needs to remain sealed from the elements to acheive a usefull service life. Your idea would work great structurally but even if the needed hole was covered with a rubber plug, condensation would still build inside and compromise the structure after a few years.

The inside of the light bar needs to remain sealed from the elements to acheive a usefull service life. Your idea would work great structurally but even if the needed hole was covered with a rubber plug, condensation would still build inside and compromise the structure after a few years.

I'm sure whatever mount HillJob26 comes up with will be brilliant (it always is). Is powder coating an option, or are you selling the light bars "ready for rattle can"? Once we get through the holidays, I'll probably be hitting you up for one.

I'm sure whatever mount HillJob26 comes up with will be brilliant (it always is). Is powder coating an option, or are you selling the light bars "ready for rattle can"? Once we get through the holidays, I'll probably be hitting you up for one.