Hunner EXtreme skids install

#1

I thought this might be useful, and since I started on this site a long time ago I wanted to make sure this was up to date.

Ok, here goes. Hunner EXtreme skids install. If you do not have the right stuff get some help and share jacks. This is not hard just print this out and go step by step. A warm dry place with good light helps. I use rubber mats instead of a creeper because of my belly, no wait, because I have more room to move around.

I like to jack up one side at a time, and I only have two jacks. I use the front spring hanger to place a floor jack under. Then I put a jackstand on the frame outside of that and put some weight on it. (I did not use it fully extended like in the picture. I lowered it and the jack part way to use both to hold it up) Then I put another one under the rear axle over closer to the wheel but just outside of where the skid is going. Now I feel sort of safe. A helper is nice if you can find one. Just as a safety and hand you things. I was not that fortunate because Im impatient.

I like to pull the wheel so I can see better. It needs to be jacked up high enough that the tire is off the ground so the springs have drooped as far as they will. Exception, the rear shock is holding the axle up by 3/4 inch. I have read where people contrive all kinds of straps and such to hold the shock up. You don't need to do that. If you use an impact, air or electric (my compressor motor fried right in the middle of this) I grabbed the electric. Use 13/16 socket and box end. I hold the nut with the box end but keep your hands away and impact the bolt head. If you do it this way the impact will screw the bolt right out as the spring and shock come down 3/4 inch more. You could be fancy and place the other jack under there and adust it 3/4 inch.

Remove the spring shackle bolts and washers. I reused the washers because some engineer thought they were needed. I sort of criscross loosening them so the nuts come off even. The shock will be hanging. Install the skid against that bottom spring plate. It should be a glove fit. Be patient "rule one" (do what I say, not what I do)

If you just gotta bang on something use a rubber coated mallet! It's a bit tricky balancing the loose washer on the nut which has a made on washer with one finger and using the other hand to get the threads started. You may now know the other reason why the hole size is slightly larger than a heavy wall 1/2 drive black impact socket for wiggle room and washing and draining. Got Mud?

Plus the elongated holes in the back bracket. There is a small nut on the bolt that holds the leaf pack together make sure it aligns with the hole in the center hole in the lower spring plate. Also watch that the upper part of the hangers are flush against the stops on the axle so they are straight down. At this point you might feel like a beer but I suggest you wait. "see rule one"

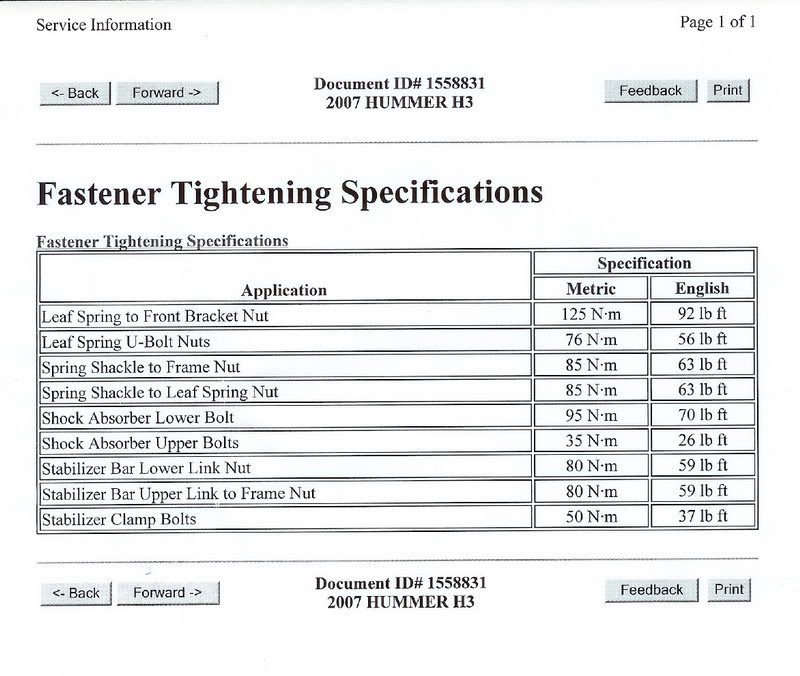

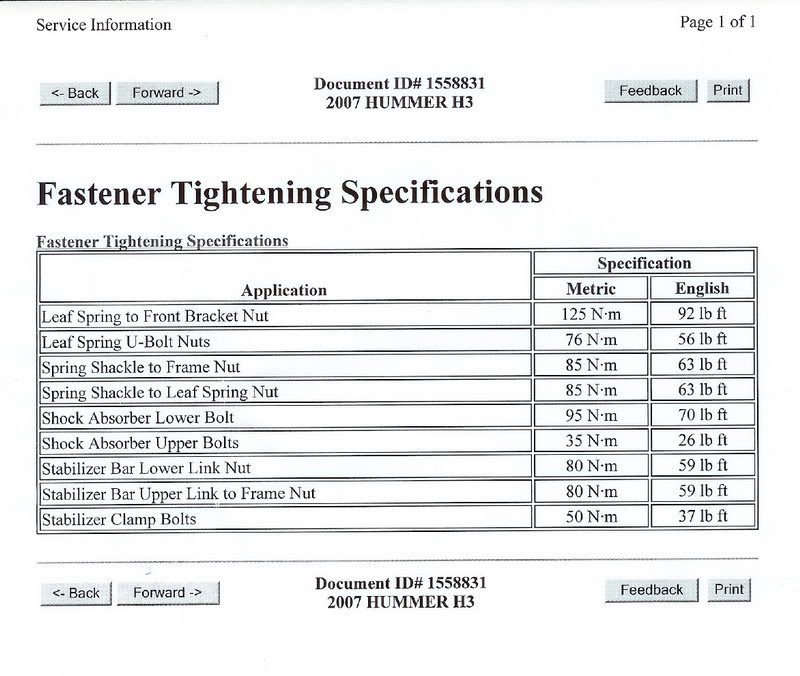

I have another smaller jack that I run up under the skid. A few pumps and the bottom eye in the shock lines up. You can remove that jack and tighten the spring bolts, again evenly in a criscross pattern. You want the same amount of thread showing on all of them to center things up. Finally either really put some grunt on a long breakover handle or read the torque chart posted to be sure.

Have a be.. oh wait (see rule one), you have to put on the wheel let the jack down and go to the other side.

Now that was not bad was it? Go wheelin smash a Priu.. uh rock.

Ok while I had everything apart I thought about when I pull the center caps to wheel really rough stuff or just long distance on unimproved roads. I hate that rusted center. Too tired to cut a template I just primed and shot it with red paint. Well surprise I got red tipped lug studs too. We havin some fun now.

If anybody sees any glaring mistakes point them out. I don't know everything, don't claim to, but I know enough to be dangerous.

Remember Hunner online help is here for you. I speak southern Arkansas dialect but I type ok English, sort of!

Don't run a jack stand all the way up like this. I had to find some block to raise it for safety.

Let the axle full droop to extend the shock. This jack stand is only used after that as a safety but not supporting the axle.

Ok, here goes. Hunner EXtreme skids install. If you do not have the right stuff get some help and share jacks. This is not hard just print this out and go step by step. A warm dry place with good light helps. I use rubber mats instead of a creeper because of my belly, no wait, because I have more room to move around.

I like to jack up one side at a time, and I only have two jacks. I use the front spring hanger to place a floor jack under. Then I put a jackstand on the frame outside of that and put some weight on it. (I did not use it fully extended like in the picture. I lowered it and the jack part way to use both to hold it up) Then I put another one under the rear axle over closer to the wheel but just outside of where the skid is going. Now I feel sort of safe. A helper is nice if you can find one. Just as a safety and hand you things. I was not that fortunate because Im impatient.

I like to pull the wheel so I can see better. It needs to be jacked up high enough that the tire is off the ground so the springs have drooped as far as they will. Exception, the rear shock is holding the axle up by 3/4 inch. I have read where people contrive all kinds of straps and such to hold the shock up. You don't need to do that. If you use an impact, air or electric (my compressor motor fried right in the middle of this) I grabbed the electric. Use 13/16 socket and box end. I hold the nut with the box end but keep your hands away and impact the bolt head. If you do it this way the impact will screw the bolt right out as the spring and shock come down 3/4 inch more. You could be fancy and place the other jack under there and adust it 3/4 inch.

Remove the spring shackle bolts and washers. I reused the washers because some engineer thought they were needed. I sort of criscross loosening them so the nuts come off even. The shock will be hanging. Install the skid against that bottom spring plate. It should be a glove fit. Be patient "rule one" (do what I say, not what I do)

If you just gotta bang on something use a rubber coated mallet! It's a bit tricky balancing the loose washer on the nut which has a made on washer with one finger and using the other hand to get the threads started. You may now know the other reason why the hole size is slightly larger than a heavy wall 1/2 drive black impact socket for wiggle room and washing and draining. Got Mud?

Plus the elongated holes in the back bracket. There is a small nut on the bolt that holds the leaf pack together make sure it aligns with the hole in the center hole in the lower spring plate. Also watch that the upper part of the hangers are flush against the stops on the axle so they are straight down. At this point you might feel like a beer but I suggest you wait. "see rule one"

I have another smaller jack that I run up under the skid. A few pumps and the bottom eye in the shock lines up. You can remove that jack and tighten the spring bolts, again evenly in a criscross pattern. You want the same amount of thread showing on all of them to center things up. Finally either really put some grunt on a long breakover handle or read the torque chart posted to be sure.

Have a be.. oh wait (see rule one), you have to put on the wheel let the jack down and go to the other side.

Now that was not bad was it? Go wheelin smash a Priu.. uh rock.

Ok while I had everything apart I thought about when I pull the center caps to wheel really rough stuff or just long distance on unimproved roads. I hate that rusted center. Too tired to cut a template I just primed and shot it with red paint. Well surprise I got red tipped lug studs too. We havin some fun now.

If anybody sees any glaring mistakes point them out. I don't know everything, don't claim to, but I know enough to be dangerous.

Remember Hunner online help is here for you. I speak southern Arkansas dialect but I type ok English, sort of!

Don't run a jack stand all the way up like this. I had to find some block to raise it for safety.

Let the axle full droop to extend the shock. This jack stand is only used after that as a safety but not supporting the axle.

Last edited by Hunner; 01-29-2012 at 08:04 PM.

Thread

Thread Starter

Forum

Replies

Last Post

05mudiak

PRIVATE For Sale / Trade Classifieds

0

01-21-2014 11:25 PM

Hunner

PRIVATE For Sale / Trade Classifieds

34

09-07-2012 07:02 PM